Author: Dave Marshall-George, Sales Director, Condair Ltd

Dehumidifiers - A Contractors' Guide

Lowering the humidity in a room can be a complicated task. The drying of air can have a dramatic impact on its temperature and, depending on the type of dehumidifier being used, there can be various installation obstacles to overcome. So what should a contractor consider before setting out on a drying project?

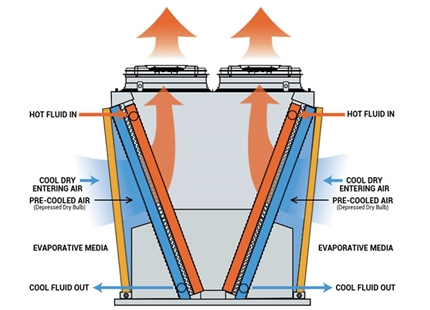

Firstly, which technology to use? There are two main types – condensing and desiccant. A condensing system collects moisture by condensing it on a cold surface and then sending it to drain. A desiccant literally adsorbs moisture by passing air through a desiccant rotor.

Due to the nature of condensing systems, they work better in warmer conditions, as more condensation occurs. This technology is ideal in rooms of 20°C or more and for projects that need to lower humidity down to around 45-50%RH. As the room’s temperature has no impact on the ability of the desiccant to adsorb moisture, it can be used in any temperature, making it a more flexible solution and ideal for cold environments. This technology is also able to lower humidity below 45%RH.

Installing a condensing system is potentially simpler as it only requires connections for power and drain. A desiccant dehumidifier doesn’t need a drain but does need a duct to vent hot wet air away from the area being dried. To remove moisture from the desiccant rotor, a secondary hot airstream is passed through the rotor, which carries the moisture away to outside.

Pressure management must be considered whenever a dehum has ducting. Each model has a pressure rating and inadequate or excessive airflow through the system may reduce efficiency or cause wetting issues. As there are two airflows through a desiccant system, care must also be taken to avoid crossflow through the rotor. Installing short ducts on both intakes will allow for dampers to be fitted, which can help manage internal pressure and avoid cross flow issues.

Alongside pressure, temperature management must also be reviewed by the contractor. The thermodynamic principle of drying produces heat at around 680W per kg of moisture extracted. In addition to this, the mechanical elements incorporated into both technologies produce heat. Without assessing and controlling this, the area being dried can experience significant heat gain.

All too frequently, the heat gain from dehumidification is countered by venting an area. But opening windows or proactively bringing in outside air, can reintroduce moisture and impact humidity control. For condensing systems, if the heat gain is too great, some units, such as the Condair DC-N, have a secondary condenser that can be located outside. This is similar to a split air con unit and allows the heat in the refrigerant loop to be remotely exhausted and the dry air delivered to the room at a precise temperature and humidity.

Installing a condensing system is potentially simpler as it only requires connections for power and drain.

Heat gain in desiccant systems will be greater than condensing, as the “regeneration” portion of the desiccant wheel is heated to remove the moisture. This heat transfers to the process airflow as the rotor revolves, so adds significant heat to the dry airflow. To counter this, a contractor can install a cooling coil before or after the dehumidifier.

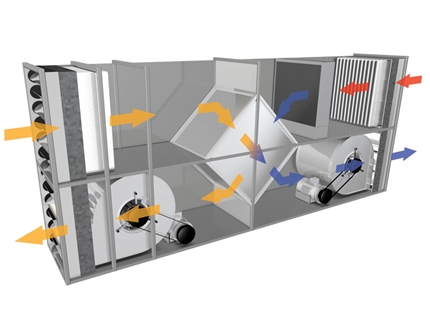

Dehumidifier location is another important decision to be made early in the project. If the unit is placed inside the area to be dehumidified, installation can be simpler with less ducting needed to direct airflows. Air can be taken from the area being dried and delivered directly back to it. Using the room air rather than outside air for the intake airflow can be more consistent in its condition, and therefore lead to more accurate humidity control. Internal air often has less moisture than outside air, potentially resulting in a smaller dehumidifier being needed.

However, many other location and airflow configurations are available, including supply air being drawn from outside to over-pressurize an area and prevent air ingress. For areas that want a pressure-neutral arrangement with a desiccant system, the regeneration airstream can intake and exhaust externally, with the process air coming from and being delivered air back to the room being treated. Understanding exactly what internal conditions are required by the client’s team will help a contractor liaise with the supplier to find the best location and airflow set-up.

Many other questions also need to be asked by the contractor to determine the size of unit needed. To provide a dehumidifier with an adequate capacity, a supplier will need to know what the required room condition is, the size of the space (and therefore air volume), and how much air exchange takes place in the area. This might be through open doors or windows, or via an air handling unit.

If the area is naturally ventilated, air exchange estimates need to be made and knowing how many doors, their size and how often they open is essential information. In addition to these factors, the number of people in the area and their activities is required along with any open sources of water. Giving this information to the supplier will allow a psychrometric calculation to be performed and a suitably sized unit to be offered.

A quality supplier will be able and happy to give advice on sizing information, along with all the other issues mentioned above. But it greatly helps avoid common pitfalls and deliver a successful project if these topics are considered as early in a dehumidifier project as possible.