Author: Nicole Jones, Technical Product Manager, Condair

Hybrid Cooling Systems: Bridging Efficiency and Sustainability

Cooling systems are essential across a variety of industries, from data centres and power plants to commercial buildings and manufacturing facilities. As environmental regulations tighten and energy costs rise, businesses are increasingly seeking solutions that balance efficiency, sustainability, and operational flexibility. One solution gaining traction is hybrid cooling, which combines the best features of evaporative and mechanical cooling systems.

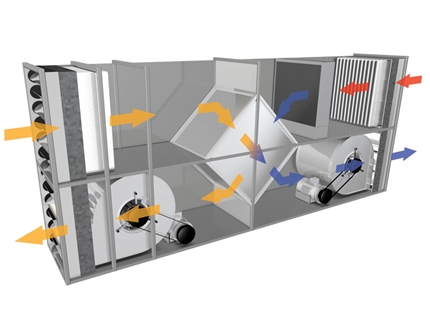

At its core, a hybrid cooling system combines two or more cooling technologies to deliver optimized performance. Typically, this involves a blend of evaporative cooling, which uses water to absorb heat from the air, and mechanical refrigeration, which relies on compressors and refrigerants.

How Hybrid Cooling Systems Adjust to Changing Conditions

Dry Air Cooling Mode: In moderate outdoor temperatures with low humidity, the system utilizes dry air cooling. This mode consumes minimal water and energy, making it ideal for cooler months or nighttime operations.

Evaporative Cooling Mode: As temperatures rise and humidity remains low, the system switches to evaporative cooling. Water evaporation significantly lowers air temperature, enhancing cooling efficiency while still conserving energy compared to mechanical methods.

Mechanical Cooling Mode: During high humidity or extreme heat, evaporative cooling becomes less effective. In such conditions, the hybrid system activates mechanical cooling to maintain desired temperature levels. This ensures consistent performance even in challenging climates.

The system’s advanced controls continuously monitor ambient conditions such as temperature, humidity, and air pressure to make real-time decisions. This intelligent modulation not only ensures optimal cooling performance but also helps balance energy consumption and water usage based on prevailing environmental factors.

Core components and their roles

A hybrid cooling system is a carefully designed network of components, each crucial for its efficiency and reliability:

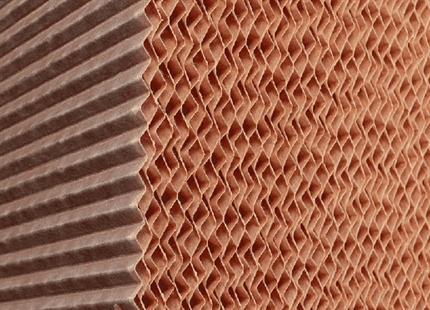

Evaporative Cooling Elements: These include high-pressure and low-pressure spray systems, along with evaporative media, that help cool incoming air through water evaporation.

Mechanical Refrigeration Units: Comprising compressors, condensers, evaporators, and expansion valves, these units engage when evaporative methods are less effective.

Control Systems: Equipped with advanced sensors and programmable logic controllers (PLCs), these systems monitor and adjust operations for maximum efficiency.

Air Handling Components: Fans, ductwork, and dampers ensure even air distribution and effective temperature management.

Heat Rejection Devices: Hybrid cooling towers and adiabatic coolers remove excess heat while minimizing water consumption.

Benefits of hybrid cooling

Organizations often wonder why they should consider investing in hybrid cooling solutions. By integrating dry air cooling, evaporative cooling, and mechanical cooling into a single system, hybrid solutions provide a wide range of benefits that address key concerns like energy efficiency, water conservation, operational flexibility, and long-term cost savings. Here are some real-world considerations:

1. Enhanced Energy Efficiency

Hybrid cooling systems allow for the most energy-efficient cooling method to be used based on real-time ambient conditions. The system strategically switches between modes to minimize energy consumption:

This dynamic adaptability reduces overall energy consumption, making it possible to maintain optimal cooling performance without wasting resources.

2. Optimized Water Conservation

Hybrid systems excel at optimizing water usage, an area where traditional cooling methods often fall short. While evaporative cooling can require large amounts of water, hybrid systems intelligently switch to dry cooling or mechanical cooling when water availability is limited or when humidity is high. This switching mechanism ensures water consumption is minimized while still providing the necessary cooling performance. Moreover, regular maintenance of evaporative media and a well-managed water system ensures that water is used efficiently, avoiding excess consumption.

3. Adaptability Across Diverse Climate Conditions

One of the standout features of hybrid cooling systems is their ability to adapt to diverse climate conditions. It performs well in arid and humid conditions. This ability to dynamically respond to changing climates makes hybrid cooling systems ideal for year-round use, no matter the geographical location.

4. Long-Term Cost Savings and Operational Flexibility

Though the upfront investment in hybrid systems may be higher than traditional methods, the long-term savings are substantial. These savings come from the system’s ability to adapt in real-time and use the most cost-effective cooling method at any given moment:

By reducing the need for mechanical cooling, the system puts less strain on equipment, extending its lifespan and reducing repair and replacement costs.

Design and engineering considerations

Designing an effective hybrid cooling solution requires a strategic and tailored approach. Several key factors must be carefully considered to ensure that the system operates efficiently, meets operational needs, and aligns with sustainability and regulatory goals.

1. Operational Needs

Assess the peak load, daily fluctuations, and typical cooling demands to determine the system’s size and capacity. For facilities such as data centers or hospitals, redundancy is critical to ensure continuous cooling during operations, even during system failures or maintenance periods.

2. Climate Data

Review local temperature extremes, humidity levels, and seasonal variations to predict the frequency with which each cooling mode (dry, evaporative, mechanical) will be activated. In regions with high humidity, design considerations should focus on enhanced mechanical cooling capacity. Conversely, arid climates benefit more from evaporative solutions.

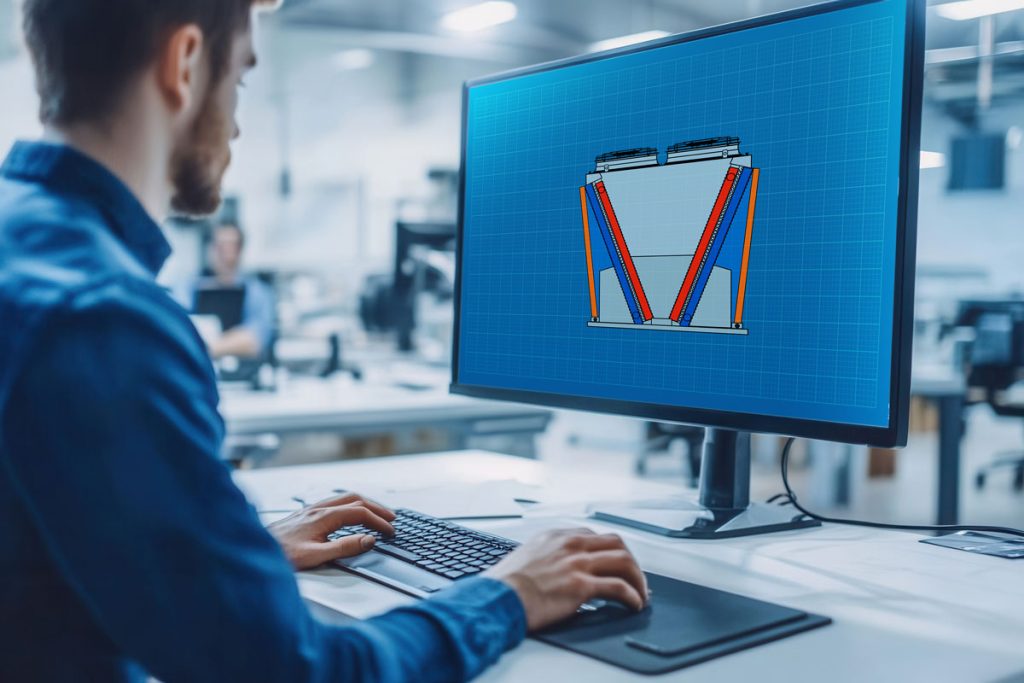

3. Building Management System (BMS) and Automation Integration

Integrating the hybrid cooling system with a Building Management System (BMS) facilitates coordination with other building systems like HVAC, lighting, and security. Automation allows for real-time mode switching based on environmental data gathered through advanced sensors. Automation not only provides predictive maintenance alerts but can also incorporate artificial intelligence (AI) to improve system efficiency by learning usage patterns and making proactive adjustments.

4. Financial Goals

Evaluate capital expenditure (CapEx) and long-term operational savings (OpEx), including reduced maintenance and energy consumption. While hybrid systems may have higher upfront costs, they deliver substantial savings in energy and water use over time, ultimately lowering the total cost of ownership.

5. Regulatory Compliance

Ensure the system complies with local and international standards like ASHRAE 90.1 (energy efficiency), ISO 50001 (energy management), and LEED certification requirements. Pay close attention to regional regulations related to water consumption and discharge to avoid compliance issues and penalties.

6. Maintenance Plans

Develop a maintenance strategy that includes water treatment to prevent scaling, fouling, and corrosion, ensuring optimal system performance. Utilize automation and IoT-enabled sensors to monitor system health, predict failures, and minimize unplanned downtime. Establish regular inspection routines for evaporative media, mechanical components, and control systems to extend the system’s lifespan and ensure consistent performance.

These design and engineering considerations ensure that hybrid cooling systems not only deliver efficiency and cost savings but are also adaptable to the unique needs of each operational environment while aligning with sustainability and regulatory goals.

Conclusion

Hybrid cooling systems deliver a balanced approach to efficiency, sustainability, and operational flexibility by integrating dry air cooling, and mechanical refrigeration. As industries navigate evolving regulatory and environmental demands, these systems provide a future- ready solution, particularly in water-sensitive regions and retrofit applications.

Condair specializes in developing tailored hybrid cooling solutions that align with your facility’s specific needs. Our expertise ensures optimized performance, energy savings, and compliance with evolving industry standards. Contact our team to explore how a hybrid cooling system can enhance your operations.